-

From Industry 4.0 to Construction 4.0: Technology Transfer from the Smart Factory to the Construction Sector.

Angelica Rocco

PhD Candidate, Università degli Studi di Napoli Federico II, Napoli, Italy

*Corresponding Author Email: angelica.rocco@unina.it

Innovation Insights, Volume No: 1, Issue No: 1 and Page 102-124

Download PDF (Article)

Abstract

The current technological progress is significantly transforming society, initiating a new chapter in human evolution. Presently known as the “Fourth Industrial Revolution,” this phenomenon features the growing convergence of the digital and physical spheres, offering exceptional potential for the establishment of unparalleled transformations across industries. With the capacity to overcome temporal, spatial, and virtual barriers, technological innovations are generating a momentous impact on global economies. This article is an investigation into the successful integration of essential Industry 4.0 technologies in the construction industry. These technologies present an opportunity to enhance efficiency, productivity and sustainability. However, it is crucial to consider the potential risks and challenges arising from their widespread adoption, including issues concerning privacy, security and ethics. Therefore, it is crucial to consider the design, development, and implementation of these technologies so that their benefits are maximised and their risks diminished. This study undertakes a thorough analysis of the scientific literature and examines the nine essential principles of Industry 4.0. Applying the Industry 4.0 paradigm to Smart Factories and extending it to the construction industry is expected to significantly improve energy efficiency, sustainability, and overall quality of life throughout the entire life cycle.

Keywords: Smart Factory, architecture, engineering and construction sector (AEC), BIM( Building Information Modeling), IoT ( Internet of things), artificial intelligence(AI).

Introduction

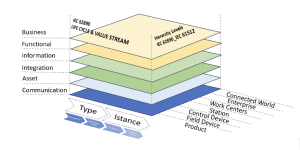

The rapid transformation in society, brought on by technological advancement, is paving the way for a new era in human development. The steady stream of technological innovations have led to substantial differences in our day-to-day lives, as well as in society and industry. This period marks the fourth industrial revolution, wherein the discrepancy between the digital and physical realms is being narrowed until they are fully integrated.The Fourth Industrial Revolution has the potential to drive rapid transformations across every sector, thereby impacting global economies. The industrial sector, serving as the economic backbone of each nation, constantly seeks innovation and technological advancements to meet challenges of quality, efficiency, and competitiveness. Industrial technology has progressed from Henry Ford’s assembly line to the computerization era, with a gradual substitution of human interaction by physical systems[1]. Since the start of the 21st century, the rising significance of intelligent digital technologies in industry, particularly in the field of next-generation intelligent manufacturing, has led society towards the fourth industrial revolution. 0 To redefine the development paradigm, technological advances will enable us to efficiently manage data, enhance productivity, customise products, and adapt to risks such as past pandemics. Real-time and remote simulations have the potential to create sustainable operations and resilient systems[2], [3][4], [5]. Countries, globally, are participating in the new industrial revolution: the United States has introduced the Advanced Manufacturing Partnership [6], Germany has launched Industry 4.0 [7], the United Kingdom has presented the UK Industry 2050 strategy [8], France has launched the New Industrial France program [9], Japan follows the Society 5.0 strategy [10], and Korea has started the Manufacturing Innovation 3.0 program [11]. Promoting smart manufacturing is seen as a key element in gaining competitive advantages in the manufacturing industry globally. In particular, the Made in China 2025 plan [12], previously known as China Manufacturing 2025, emphasizes promoting smart manufacturing through the in-depth integration of next-generation information technologies into the manufacturing industry. Industry 4.0 encompasses various concepts, processes, and technologies [13]. Critical technologies required to facilitate this transformation involve cloud computing, the Internet of Things (IoT), the Industrial Internet of Things (IIoT), cyber-physical systems (CPS), advanced materials, additive manufacturing, artificial intelligence, machine learning, cybersecurity, big data analytics, cognitive computing, autonomous robots, and mobile services [14]–[16][17], [18].Although many of Industry 4.0’s technologies are already in use, the involved actors often lack the necessary knowledge to fully utilize their potential. To overcome this issue, several German organizations have worked together to develop a reference model (Fig. 1). The model establishes a structured framework that delineates the basic principles of Industry 4.0, thus forming a shared and unified language[19].In the 3D model, the horizontal axis on the left, adhering to the IEC 62.890 standard, illustrates plants and the product life cycle along with their respective value streams. This model establishes a clear differentiation between “instance” and “type”, where the latter refers to the prototype being prepared for production after the design phase’s completion. The hierarchical levels outlined by the IEC 62264 standard are represented on the right vertical axis, with each entity corresponding to a different level in the enterprise hierarchy. From the lowest level, “Product,” to the highest level, “Connect World,” which utilises IoT and IoS to connect businesses, customers, and suppliers[20], [21]. The layers on the vertical axis serve as a reference for ensuring complete digital integration across all aspects. The vertical axis layers direct the incorporation of the corporate digitalization aspect and comprise of, as per multiple sources [22], [23], [24]: 1) The Asset Layer represents the physical components of reality, such as robots, conveyor belts, archives and people, with linear axes connected to the virtual world. The Integration Layer processes information for resource digitisation by connecting business elements with information technology, including sensors. The Communication Layer standardises communication by using uniform data formats and predefined protocols for the Integration Layer. The information layer processes and integrates data, enabling it to be used at the next level. The functional layer generates rules and logic on a platform accessible remotely. The business layer connects various models in order to maintain the integrity of functions within the value stream.

This model (Fig. 1) enables the objective identification of key aspects within Industry 4.0, while also aiding the gradual transition from extant production mechanisms to those of the future. Moreover, it promotes tech transfer to other production sectors.

ObjectiveThe aim of this investigation is to delineate the technological aspects initiated by the fourth industrial revolution and implemented in other industries, with a specific focus on the construction sector. The main objectives of this study are to recognize the technologies applied in the sophisticated fabricating process of construction materials in Smart Factories and to investigate their usage in Construction 4.0 beyond the conventional industrial milieu. This represents a pivotal moment for comprehending and predicting future advancements within the Architecture, Engineering, and Construction (AEC) industry.

Methodology

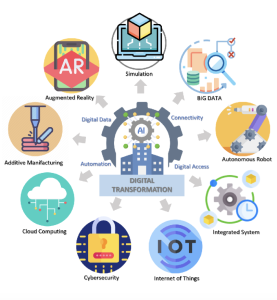

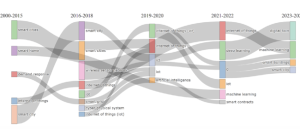

The scientific literature was analysed following the nine pillars of Industry I.4. The aim was to showcase the technology employed and develop a standardised comprehension on various levels. This allowed for the differentiation between individual technologies and their class. A bibliographic review was undertaken to identify which Industry4.0 technologies have been adapted for Construction4.0. The study commences with gathering scientific literature that centres on keywords like “smart building” and “key technologies.” This aims to comprehend the most commonly adopted enabling technologies in the construction industry, followed by a comprehensive discussion on each of these (refer to fig. 2).

Results

Figure 2 illustrates the thematic progression of Keyword Plus in Scopus and Web of Science from 2000 to 2021, in comparison to the search queries in fig.1. The graph depicts the evolution of technological transfer from Industry 4.0 to the construction sector between 2000 and present day. It can be concluded that this accomplishment was primarily due to the Internet of Things (IoT) and the implementation of sensors. The Internet of Things (IoT) has led to the spread of other technologies, including Cyber Physical Systems (CPS), information and communication technologies (ICT), artificial intelligence (AI), machine learning (ML) and deep learning (DL) and Smart Contracts (SM). Additionally, while the Industry 4.0 product is housed within the Smart Factory, the Construction 4.0 product emphasises the Digital Twin (DT), which represents the virtual model of the Smart Building and the Smart City.

From the Smart Factory to Construction 4.0.

Recent advancements in data acquisition, digital analytics, and automated construction technologies are propelling the construction industry towards digital transformation, referred to as Construction 4.0. This transformation integrates cutting-edge technologies including building information modeling, extended reality, Internet of Things, artificial intelligence, machine learning, big data, nanotechnology, and 3D printing [25]. In order to comprehend the transition to Construction 4.0, the characterizing factors of Industry 4.0, with the Smart Factory as its model, must be analyzed. The Smart Factory, utilizing enabling technologies (KETS) and information communication technologies (ICT), enhances the efficiency, quality, manageability, supervision, and transparency of production processes. Compared to conventional manufacturing processes, the smart factory empowers manufacturers to address customer needs by adjusting production specifications and other machine settings even at the eleventh hour [26].

Figure 3: The nine pillars of I4.0

The smart factory signifies a shift from conventional automation to a highly interconnected and versatile system. This system is characterized by a continuous flow of data through closely linked production systems and operations [27]. These factories have the ability to assimilate data from physical, operational, and human resources, learn quickly, and adapt to fluctuating demands. The primary objective is to effectively establish interconnected manufacturing facilities utilizing intelligent production systems and relevant engineering methodologies. Within a smart factory setting, the manufacturer can address customer requirements through modifications to production specifications and other machinery configurations, thereby reducing the occurrence of operational disruptions and other potential production setbacks. The framework comprises nine pillars that facilitate an interface between the physical and cyber worlds, utilizing the potential of 6G networks and Artificial Intelligence. It can efficiently gather data from sensors and execute corrective actions in real-time, automating and optimizing production processes that were traditionally carried out by humans. [28] This model has contributed to the definition of virtual representations of physical systems, enabling the monitoring and prediction of operations across various sectors. Additionally, it has played a role in the digital transformation of the construction industry (fig.3). In Construction 4.0, BIM (Building Information Modelling) facilitates the technological transition by integrating building information throughout the life cycle of a building, encompassing design, construction, operation, maintenance, as well as reuse or demolition [28]. The integration of Building Information Modelling (BIM) with augmented reality provides an optimized decision-making process. This allows for predictive visualizations of the project progress during operations on site. BIM contributes to structural checks during the design phase [29], with automated construction implementation such as 3D printing [30],energy efficiency practices through simulation [31], and promotes a collaborative environment where different players in the construction industry can meet in a virtual setting and in real-time[32]. In the early stages of BIM design, 3D laser technology is crucial for detecting buildings and water pipes by digitally capturing their dimensions and spatial relationships. The collected data can be integrated into BIM projects, enabling work teams to facilitate digital planning [33].

Internet of Things (IoT).

In addition to BIM, the Internet of Things (IoT) constitutes a potential technological advancement that has the capacity to significantly transform the construction industry. The system interconnects objects via the Internet using wireless or wired connections, as well as cloud computing infrastructures via integrated or connected sensors [34]. Sensors facilitate the connection and communication between devices and systems, detecting environmental stimuli and processing data autonomously by evaluating environmental conditions. They reduce human errors by improving quality and productivity and minimizing constant monitoring operations[35], [36]. These improvements enhance the efficiency of production processes by enabling real-time data collection, remote surveillance, preventive maintenance, and the assessment of object characteristics, such as location, distance, proximity, temperature, and colour[37], [38]. These measurements aid in monitoring all stages of the construction cycle. Nonetheless, multiple sensor options are available in the market.A temperature sensor can identify temperature from a source and convert it into data that other devices can interpret. Temperature directly impacts construction quality and material properties. The categorisation of sensors separates them into two categories: (1) low-temperature sensors, with a range between −100 and +400 °C, which use materials like phosphors, semiconductors and liquid crystals; and (2) high-temperature sensors, with a range between 500 and 2000 °C, that rely on blackbody radiation [39]. Barometric pressure sensors, capable of identifying atmospheric fluctuations, are fundamental for environmental assessments and calculating the energy demands of buildings. Position sensors are utilized to identify the placement of construction elements and components, serving as a valuable tool for the traceability of building materials within the construction supply chain. The inputs of pallets containing construction materials on a construction site can be calculated using motion or proximity sensors. Force sensors convert applied forces, such as traction or compression, into electrical signals representing the degree of force. These signals are then transmitted to Cyber Physical Systems, providing information to operators about processes or acting as inputs to control machinery and procedures. These sensors are crucial for technological advances in the production of advanced materials within the construction sector. Flow sensors, which utilize ultrasonic flow detection, allow for improved management of the production process for cellulose-based insulation[44].Technological progress has played a significant role in the proliferation of smart, compact, and adaptable sensors, capable of carrying out intricate computations on the information gathered by means of the incorporation of signal conditioning, algorithms, and digital interfaces, thereby evolving into self-aware apparatuses [45].This category of sensors can accumulate an array of data, detect motion, supervise and forecast situations in real-time, and take immediate remedial measures. Smart sensors play a crucial role in the construction industry. They can detect faults in architectural products, leading to substantial savings in maintenance costs. Microsensors are among the latest generation smart sensors and are capable of converting mechanical signals into electrical signals. They can measure temperatures, pressures, forces, speed, sounds, magnetic fields, and they also use nanosensors (NEMS), based on nanotechnology for detection

Fortino [48]devised an interoperable model for the Internet of Things (IoT), using a layered approach consisting of five layers: gateway/virtual devices, network, middleware, application services, and data and semantics. The model aims to amalgamate data from diverse IoT platforms to enhance product performance, modularity, adaptability, and flexibility. Consistent citation and clear quotation indication will be ensured, with stylistic standards adhered to in the footnote style and formatting features. This model, applied to the construction supply chain, possesses the potential for monitoring and detecting all phases of the lifecycle of architectural items including the production of building materials, through to the decommissioning of the buildings.

Simulation.: Simulation is an operational process that reproduces a real-world system or process over time, enabling information to be extracted about the operational characteristics of the real system through observation of its simulated representation. Simulation enables the conduct of experiments for product and process validation, as well as system design and configuration. This helps to decrease costs, shorten development cycles, and enhance product quality before market placement. The fundamental aspect of simulation is the definition of the model. The selection of a simulation model hinges on numerous factors, including the use of static models for stable structures and dynamic models for evolving systems that support long-term design, such as system capacity and material handling means. Offline simulation is a helpful tool for analyzing hypothetical scenarios and the actual performance of the operational process (known as online). The parametric simulation modelling paradigm is founded on the notion of Digital Twin (DT). Simulations span all stages of the product life cycle and incorporate actual data into simulation models, thus enhancing their efficacy. Additionally, to further specify Big Data, other dimensions have been suggested including truthfulness, vision, volatility, verification, validation, variability, and value. Advanced Big Data analytics is essential for comprehending the different stages of the life cycle.By transferring the data obtained from IoT to cloud computing, both real-time and offline data can be analyzed with methods such as machine learning and prediction models. This process facilitates the extraction of knowledge from vast data, enabling an in-depth comprehension of the product lifecycle stages. Advanced big data analytics also aid in identifying and eliminating barriers created by IoT-generated data. In the construction industry, it is feasible to incorporate artificial intelligence in the autonomous operation of cranes to enhance logistics and site operations for modular construction.

Horizontal and Vertical Systems Integration

Horizontal and vertical integration enables real-time data sharing for enhanced LCA assessments by digitalizing capable processes that comply with the standards underlying the vertical system.This complete digital procedure ensures that the end-of-life product is reintroduced into the system as an additional raw material. However, this technology remains an overlooked area in Construction 4.0 (C4.0) research. Horizontal integration, especially significant in Civil Engineering, indicates an increasing interest in new sectors like Blockchain technology and smart contracts, which provide substantial prospects for the development of the construction supply chain. Adopting Blockchain technology on Digital Twin models can enhance the functionality of artificial intelligence by ensuring data security and enabling access to pertinent information from multiple data layers. Blockchain’s features that ensure privacy and security can also promote data sharing amongst various actors in the AEC industry.

Discussion

The transfer of technology from Industry 4.0 to the construction sector through Construction 4.0 will yield numerous benefits that will facilitate supervision and regulation throughout all stages of design, associated with the life cycle of construction materials and structures. In the future, it will be feasible to execute automated construction not exclusively for the production of building materials, but also for all undertakings on construction sites. This will be achievable through the examination of data acquired from process digitalisation and utilisation of advanced information and communication technologies. Meanwhile, Information Technology and Communication automate manual procedures to simplify the process.

Conclusion

The past ten years have seen substantial changes in the technologies and processes used in the construction sector. The ideas associated with Industry 4.0 are now evident in construction 4.0.The central catalysts for this transformation are the digitisation and interconnectivity of the cyber-physicalsystems within the sector. Construction 4.0 offers a multitude of technologies and related processes throughout the lifecycleof a construction project. Meeting the challenges of an ever-evolving world, the construction industry is embracing technological innovation. The digital revolution and shortage of skilled labour within the field of construction have emerged as critical issues, speeding up this transformation. The widespread adoption of advanced technologies, including IoT, BIM and digital systems, is giving rise to a new era in construction, known as Construction 4.0. This scenario has the potential to enhance productivity, quality, cost-effectiveness, and resource efficiency in the construction sector, while also enabling tracking and monitoring of all project phases and architectural life cycles.

Reconstructing the knowledge flow linked to technological transfer from Industry 4.0 to the AEC sector will be useful in understanding the applicability and implementation of key enabling technologies and ITC in the AEC sector.

References

[1] J. Zhou, P. Li, Y. Zhou, B. Wang, J. Zang, and L. Meng, “Toward New-Generation Intelligent Manufacturing,” Engineering, vol. 4, no. 1, pp. 11–20, Feb. 2018, doi: 10.1016/j.eng.2018.01.002.

[2] J. , N. J. , & W. A. Z. Lee, “ From big data to intelligent manufacturing.,” Shanghai Jiao Tong University: Shanghai, China., 2016.

[3] J. , Q. B. , L. Z. , & W. M. Lee, “Cyber-physical system: The new-generation of industrial intelligence,” 2017.

[4] F. Tao, Q. Qi, L. Wang, and A. Y. C. Nee, “Digital Twins and Cyber–Physical Systems toward Smart Manufacturing and Industry 4.0: Correlation and Comparison,” Engineering, vol. 5, no. 4, pp. 653–661, Aug. 2019, doi: 10.1016/j.eng.2019.01.014.

[5] W. D. Lin and M. Y. H. Low, “Concept Design of a System Architecture for a Manufacturing Cyber-physical Digital Twin System,” in 2020 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), IEEE, Dec. 2020, pp. 1320–1324. doi: 10.1109/IEEM45057.2020.9309795.

[6] N. S. and T. Council. Executive Office of the President, “A national strategic plan for advanced manufacturing. ,” Washington, DC, 2012.

[7] W. W. H. J. Kagermann H, “Recommendations for implementing the strategic initiative Industrie 4.0: Final report of the Industrie 4.0 Working Group. ,” Munich, 2013.

[8] Foresight., “The future of manufacturing: A new era of opportunity and challenge for the UK. ,” London:, 2013.

[9] Government of the French Republic, “The new face of industry in France,” Paris:, 2017.

[10] H. Taki, “Towards technological innovation of Society 5.0,” J Inst Electr Eng Jpn, 137 , p. 275, 2017.

[11] S.Y. Han, “Industry Innovation 3.0,” APO News, vol. 44, no. 4, p. 8, 2014.

[12] State Council of the People’s Republic of China., Made in China 2025. Beijing: http://www.gov.cn/zhengce/content/2015-05/19/content_9784.htm, 2015.

[13] P. F. H. G. K. T. F. and M. H. H. Lasi, “Industry 4.0 ,” Bus. Inf. Syst. Eng., vol. 6, no. 4, pp. 239–242, 2014.

[14] V. Alcácer and V. Cruz-Machado, “Scanning the Industry 4.0: A Literature Review on Technologies for Manufacturing Systems,” Engineering Science and Technology, an International Journal, vol. 22, no. 3, pp. 899–919, Jun. 2019, doi: 10.1016/j.jestch.2019.01.006.

[15] M. N. Sadiku, Emerging internet-based technologies., vol. CRC Press. 2019.

[16] A. , P. M. E. , D. L. H. A. , & C. A. Luque, “ State of the Industry 4.0 in the Andalusian food sector.,” Procedia Manuf, vol. 13, pp. 1199–1205, 2017.

[17] F. Baena, A. Guarin, J. Mora, J. Sauza, and S. Retat, “Learning Factory: The Path to Industry 4.0,” Procedia Manuf, vol. 9, pp. 73–80, 2017, doi: 10.1016/j.promfg.2017.04.022.

[18] M. Peruzzini, F. Grandi, and M. Pellicciari, “Benchmarking of Tools for User Experience Analysis in Industry 4.0,” Procedia Manuf, vol. 11, pp. 806–813, 2017, doi: 10.1016/j.promfg.2017.07.182.

[19] F. Pauker, T. Frühwirth, B. Kittl, and W. Kastner, “A Systematic Approach to OPC UA Information Model Design,” Procedia CIRP, vol. 57, pp. 321–326, 2016, doi: 10.1016/j.procir.2016.11.056.

[20] A. Rojko, “Industry 4.0 Concept: Background and Overview,” International Journal of Interactive Mobile Technologies (iJIM), vol. 11, no. 5, p. 77, Jul. 2017, doi: 10.3991/ijim.v11i5.7072.

[21] F. Pauker, T. Frühwirth, B. Kittl, and W. Kastner, “A Systematic Approach to OPC UA Information Model Design,” Procedia CIRP, vol. 57, pp. 321–326, 2016, doi: 10.1016/j.procir.2016.11.056.

[22] A. Rojko, “Industry 4.0 Concept: Background and Overview,” International Journal of Interactive Mobile Technologies (iJIM), vol. 11, no. 5, p. 77, Jul. 2017, doi: 10.3991/ijim.v11i5.7072.

[23] F. Zezulka, P. Marcon, I. Vesely, and O. Sajdl, “Industry 4.0 – An Introduction in the phenomenon,” IFAC-PapersOnLine, vol. 49, no. 25, pp. 8–12, 2016, doi: 10.1016/j.ifacol.2016.12.002.

[24] P. I. 4. 0 ZVEI, “The reference Architecture Model of Industrie 4.0 (RAMI 4.0) ,” https://www.zvei.org/en/subjects/industry-4-0/the-reference-architectural-model-rami-40-and-the-industrie-40-component/.

[25] Casini M., Construction 4.0, Woodhead Publishing. Elsevier, 2022. doi: 10.1016/C2019-0-04325-7.

[26] D. Ivanov, A. Dolgui, B. Sokolov, F. Werner, and M. Ivanova, “A dynamic model and an algorithm for short-term supply chain scheduling in the smart factory industry 4.0,” Int J Prod Res, vol. 54, no. 2, pp. 386–402, Jan. 2016, doi: 10.1080/00207543.2014.999958.

[27] E. Hofmann and M. Rüsch, “Industry 4.0 and the current status as well as future prospects on logistics,” Comput Ind, vol. 89, pp. 23–34, Aug. 2017, doi: 10.1016/j.compind.2017.04.002.

[28] D. , P. X. , V. I. , & A. P. García, “BIM for pre-demolition and refurbishment inventories and waste information management.,” HISER International Conference 2017, Ed., 2017.

[29] J. P. Zhang and Z. Z. Hu, “BIM- and 4D-based integrated solution of analysis and management for conflicts and structural safety problems during construction: 1. Principles and methodologies,” Autom Constr, vol. 20, no. 2, pp. 155–166, Mar. 2011, doi: 10.1016/j.autcon.2010.09.013.

[30] O. Davtalab, A. Kazemian, and B. Khoshnevis, “Perspectives on a BIM-integrated software platform for robotic construction through Contour Crafting,” Autom Constr, vol. 89, pp. 13–23, May 2018, doi: 10.1016/j.autcon.2018.01.006.

[31] W. Natephra, A. Motamedi, N. Yabuki, and T. Fukuda, “Integrating 4D thermal information with BIM for building envelope thermal performance analysis and thermal comfort evaluation in naturally ventilated environments,” Build Environ, vol. 124, pp. 194–208, Nov. 2017, doi: 10.1016/j.buildenv.2017.08.004.

[32] T. Gerrish, K. Ruikar, M. Cook, M. Johnson, M. Phillip, and C. Lowry, “BIM application to building energy performance visualisation and management: Challenges and potential,” Energy Build, vol. 144, pp. 218–228, Jun. 2017, doi: 10.1016/j.enbuild.2017.03.032.

[33] J. Xu, L. Ding, and P. E. D. Love, “Digital reproduction of historical building ornamental components: From 3D scanning to 3D printing,” Autom Constr, vol. 76, pp. 85–96, Apr. 2017, doi: 10.1016/j.autcon.2017.01.010.

[34] Lopez Research., “ Building smarter manufacturing with the Internet of Things (IoT).,” 2014.

[35] A. Rega, S. Patalano, F. Vitolo, and S. Gerbino, “A Sensor Data Fusion-Based Locating Method for Reverse Engineering Scanning Systems,” in 2019 II Workshop on Metrology for Industry 4.0 and IoT (MetroInd4.0&IoT), IEEE, Jun. 2019, pp. 123–126. doi: 10.1109/METROI4.2019.8792864.

[36] M. Javaid, A. Haleem, R. P. Singh, S. Rab, and R. Suman, “Significance of sensors for industry 4.0: Roles, capabilities, and applications,” Sensors International, vol. 2, p. 100110, 2021, doi: 10.1016/j.sintl.2021.100110.

[37] M. Lakoju, N. Ajienka, M. A. Khanesar, P. Burnap, and D. T. Branson, “Unsupervised Learning for Product Use Activity Recognition: An Exploratory Study of a ‘Chatty Device,’” Sensors, vol. 21, no. 15, p. 4991, Jul. 2021, doi: 10.3390/s21154991.

[38] C.-H. Lo, C.-C. Chen, H. L. S. Perline, and C. M. Yoandara, “Design of Injection Molding of Side Mirror Cover,” Sensors and Materials, vol. 34, no. 6, p. 2243, Jun. 2022, doi: 10.18494/SAM3828.

[39] D. N. Le, L. Le Tuan, and M. N. Dang Tuan, “Smart-building management system: An Internet-of-Things (IoT) application business model in Vietnam,” Technol Forecast Soc Change, vol. 141, pp. 22–35, Apr. 2019, doi: 10.1016/j.techfore.2019.01.002.